In this post I provide a review of three different in-store refill operations found in the UK, specifically looking at POS dispensing and return to store along with the packaging which supports these ecosystems.

Packaging costs are rising steeply due to increases in raw materials costs, supply chain complexities and transportation, not to mention the upcoming UK plastic packaging tax. Combine these facts with a fundamental shift in consumer purchasing behaviour driven by the desire to live more sustainably, and there has never been a better time to look into refills.

With supermarkets pledging to halve their environmental impact by 2030, I thought I would visit a few looking at just one of the tools they have to help meet this target.

ASDA, York

Beauty Kitchen & Unilever – Deposit & Return

My first stop was Asda in York, and overall I was very impressed with their efforts in embracing the refill economy. There was a large section in-store dedicated to the refill of household and food items with staff on hand to help new shoppers adopt the system. The refill area was busy with interested consumers investigating the new layout and making purchases across different business units.

Alongside commonly found refill systems such as OceanSaver and Ciff EcoRefill, Asda has teamed up with Beauty Kitchen and Unilever to offer a return and deposit system.

Purchasing is very familiar to the consumer with pre-filled bottles ready to take to the till and no need to take any additional action.

The Beauty Kitchen packs come in two stainless steel forms;

- A 1215ml bottle, currently exclusively used by Persil

- A 500ml bottle used across a range of body and hand care products from different brands.

The 500ml bottles are lacquered stainless steel but this has not stopped one of mine from displaying signs of rust at the base where it has been damaged in transit. This rust is due to pitting as you may find at home on your stainless steel cutlery if you don’t take care of them

The closures are also worth further investigation;

- The 500ml bottle comes with and without pumps encouraging the consumer to keep their existing pump (pumps cannot be cleaned and reused as part of this system)

- The 500ml bottle has a SS cap with a foamed PE liner.

- The 1215ml Persil bottle has a PP cap with an over moulded TPE gasket seal.

Both of these designs show that the intent is to reuse the caps, not just the bottles. For me, this is a critical part of the offering. Caps often slip through the net of traditional MRF collection and recycling due to their size (plastic items less than 50mm are rarely recycled in the UK).

Reusable packaging uses a wide range of labelling and printing methods.

Another interesting observation is that the bottles show a wide variety of different decoration techniques, including direct printing for both resistant adhesion to remain with the bottle through multiple wash cycles, and low adhesion which can be removed with a scrubbing action during cleaning.

None of the labels I found were what I would consider easy-peel nor are there any fibrous paper labels, at this site, which would be easier to wash off. All of the labels contain batch codes meaning it’s highly likely that each one needs to be removed before the bottle can be refilled even if it’s being filled with the same product.

My take away here is that behind the scenes there are several different cleaning processes being investigated including both automatic and semi-manual.

Pack serialisation supports safe reuse and is an opportunity to gather data and talk directly to the consumer.

On the base of each bottle is a digitally printed laminated label with a unique UR code. This serialisation of assets is critical to the success of the refill ecosystem especially if you intend to refill packs with different products. This QR code can also be used to provide additional information to the consumer about this specific bottle such as how many times it has been reused, how much plastic it has saved, or its relative carbon footprint. I would like to see them going further and using this code to assign batch codes and even ingredients supporting the use of more permanent decoration techniques. This would further reduce the use of chemicals in the cleaning process and eliminate label waste which is essentially a non-recyclable by-product.

Asda, Leeds

Beauty Kitchen & Unilever – POS dispensing

At this store Asda are trialling a number of sustainable initiatives and they have rebranded their entire store.

Not strictly part of the refill offering but worth a mention is their excellent collection points for everything from soft plastics to hangers, crisp packets to small plastic toys, the latter being an area of consumerism I would love to see under a similar spotlight to FMCG packaging.

In this store, Beauty Kitchen is once again part of a trial with Unilever this time looking at a POS refill system.

In this system, the bottles are not returned to the brand for cleaning. Instead, it is cleaned by the consumer (if necessary) and refilled as required. The advantage of this system is that it eliminates additional transportation and cleaning costs, the downside, however, is the elevated complexity in-store.

Dispensing liquids in-store is complex at scale

The POS delivery system proved to be a bit of a hurdle when I tested it. There were three machines but only one was operational. The machine has a large touch screen UI that needed navigating before a purchase could be made. In theory, this looked fairly straightforward however, it repeatedly crashed when I was testing it, randomly informing me that certain products were unavailable one minute, then different ones the next, or that bottles were out of stock.

Taking a sneaky peek inside…

A member of staff joined me in the fight. After a couple of resets and a quick look inside, which allowed me to take a behind-the-scenes picture, we were up and running.

As you can see, the machine houses bespoke refillable containers, which I estimate to hold about 25l, much more than this and they would be hard to swap in and out due to their weight and location. The containers appear to be pressurised with an electrically driven open/close solenoid clamping off the silicone tube on the product outlet.

Blank empty bottles are provided and placed into the relevant dispenser slot, it’s one slot per product to avoid contamination. It takes about a minute to fill a 500ml bottle which feels like an age while you’re waiting at the machine.

The only difference as far as the bottles and the return process is concerned is that the label is printed on-demand at the point of refill. The label is paper-based which would be easy enough to remove by hand for the consumer. Alternatively, if the bottle is returned for a refund, the label could be removed by washing in a bath containing a dilution of sodium hydroxide.

Stainless Steel vs Aluminium

While talking with a member of staff I was informed that initially the system was launched with aluminium bottles but there had to be some form of recall due to a compatibility issue. I don’t have any further information on this but she did give me one of the aluminium bottles and it does indeed look to be significantly discoloured both internally and externally. From previous work in this space, I have seen a shift from plastic to aluminium as an effort to support reuse. This move can be counterproductive as aluminium dents easily and with the addition of consumer use, return and sterilisation transformations the opportunity to cause damage increases. Despite consumers requesting reuse, they are reluctant to pick visibly ‘used’ goods from the shelf.

You can see in both Asda setups there is a great deal of in-market learning and they are optimising their offering as they go. Someone always has to go first, and Beauty Kitchen is leading the way particularly in the in-store refill arena which if it can be cracked offers the highest levels of sustainability in terms of packaging and movement of materials. Watch this space for further innovation for sure.

Tesco, Milton Keynes

Loop – Deposit and Return

Much like the first Asda setup Loop have chosen to provide filled packaging where the consumer continues with their traditional purchasing behaviour.

There is a much wider selection of packaging here to look at;

Standardisation of refill assets

The 500ml & 1215ml bottles are the same stainless steel ones as used in Asda. Actually, the bottles are provided by a company called RE. I’m informed that you can return these bottles across both platforms for refunds either direct to the store or through the Loop app. This is a nice example of collaboration and simplification for the consumer. Standardisation in the refill market is another interesting discussion but one for another blog post!

Changing materials to support reuse

Bulldog products are offered in glass jars. I’m not sure what the single-use equivalent is but I have seen these in both aluminium and SAN jars.

BrewDog has a large traditional glass bottle with an over centred cam style cap but in this execution, the steel frame and silicone bung of the cap has been replaced with a glass-reinforced nylon frame with over moulded TPE gasket. Like the Beauty Kitchen bottles, it looks like they have made a conscious decision to support cap reuse.

Repurposing single use to validate consumer adoption

Naked are interesting, they have an instant noodle meal which you eat out of the pot after filling it with hot water (think Pot Noodle) but the pot is then returned so essentially Loop is cleaning a food bowl. I haven’t eaten one yet but I expect that the plastic will absorb some of the flavours of the meal and potentially colour during cooking so I’m not sure how well this pack is suited for reuse across different consumers. (Update: I have eaten them and they were delicious! I can also confirm that after a washing cycle in my dishwasher the tub remains stained by the food) The PP tub feels flimsy and very probably intended for single-use. It’s great that they are open to reuse and are active in this space but it would have been nice to see something more robust and long-lasting like a Tritan container especially as there is a £2 deposit on it. Club Zero is a good platform to look at in this space.

There are also other containers such as Heinz Tomato ketchup that seem to have used the same packaging as their existing single-use alternatives. I expect this is much like Naked in that it’s an easy first step into this space allowing the brand to quantify the value proposition. The current ketchup bottle has been light-weighted through many iterations to reduce costs whereas glass receptacles intended for reuse need to be redesigned to support the rigours of the return and sorting processes. In this case, the hexagonal design is poorly suited to a reusable glass execution. Returnable glass Coke bottles are a better example that can be returned through their dedicated channels.

Redesigned plastic packs with permanent screen printed labels

Another interesting offering is the Ecover bottle. Ecover, owned by SC Johnson along with Method, are a brand focused on reducing waste. Here their HDPE bottle has both embossed and debossed features which increase cleaning complexity. The bottle features direct printing decoration. It could be pad printed but I think due to the thickness of the ink it’s more likely to be screen printed. Screen printing offers the opportunity to eliminate the traditional label and move to a long term label that remains on the bottle through multiple reuse cycles. There are several decisions to be made when choosing such a printing technique including specialised ink selection, butane or corona surface pre-treating to break the skin tension, and after printing there is a UV finishing process to consider. Each of these variables needs to be optimised to ensure the long term success of the pack.

Cleaning bottles vs cleaning caps

Unlike their bottle, the Ecover cap is disposable. It features a living hinge that will not withstand long term use. The decision to not reuse may come down to the availability of industrial cleaning facilities. Cleaning caps requires a completely different approach to cleaning bottles. Caps need to be agitated similar to your washing machine to ensure any product which is in the small recess of the injection moulded component can be removed. Bottles on the other hand need to be held upside down and exposed to jets of water like your dishwasher.

Refill is not always the best solution

Finally, the presence of stainless steel tubs to house tablets and tea bags is a bit of a surprise. Teabags traditionally come in a thin cardboard box which is ideally suited to recycling. You can also buy sugar in similar SS containers. Currently, most consumers purchase sugar in a paper bag and dispense it into their jar at home. It’s necessary to look at the alternative when considering a deposit and return scheme; migrating from lightweight paper-based containers to heavy steel containers which need to be brought back to the store, transported to a cleaning site, sterilised and then sent to the filling line does not seem to stack up.

Reusable dishwashing tablet containers make a little more sense as they would eliminate the use of a thick flexible pouch or thermoformed tub. For both teabags and laundry pods, surely the best solution is to have a dispenser similar to that used for dry foods eliminating the need to return any packaging. This approach would allow brands to invest in a better keep at home child-safe container which would, in turn, elevate the brand.

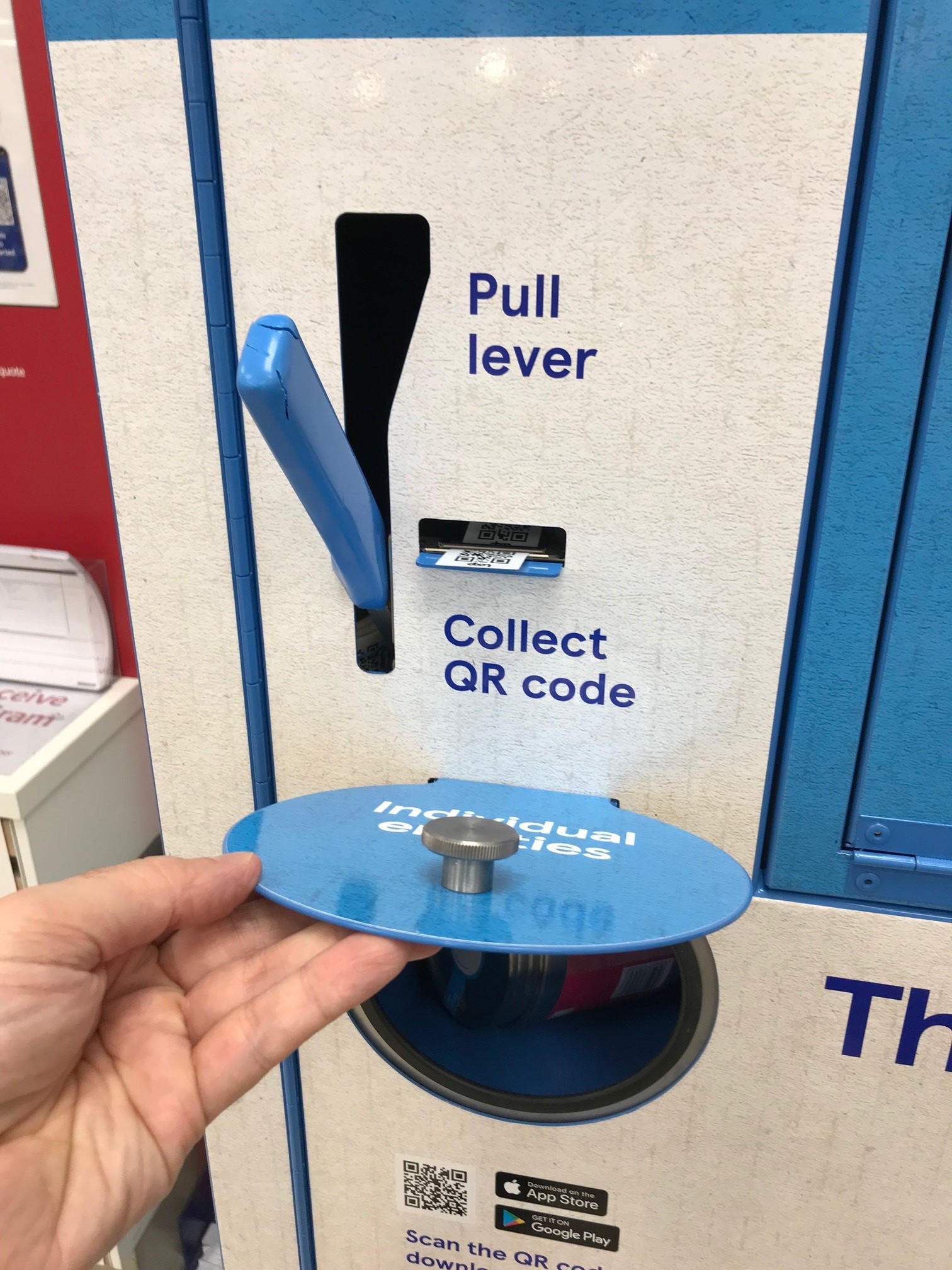

Keep it simple – the return process

The consumer-facing return portion of the loop system is well thought out and simple. The return station contains no obvious power connections relying on your phone to track the returns. Removing complicated interfaces from in-store systems, be it at return or collection, offers the lowest cost and reduces items that need to be serviced as a result of a malfunction.

To return your pack, just pull the lever on the outside of the machine to expel a pre-printed QR code sticker. These stickers are digitally printed to achieve a roll of unique ID’s. Once the sticker is applied to your bottle it’s scanned with the app on your phone and placed into the hopper. You are then credited with the returned deposit, I think once the pack has been received from the collection point.

As you can see there’s quite some movement in this space. I expect the offerings to change, the brands involved to grow, and based on the amount of activity I witnessed in all three stores, the uptake to increase. For a career-long packaging engineer, it’s an exciting time to be working in the industry.

Ben Colman

Arne.Studio is a creative engineering consultancy focusing on FMCG specifically the design and development of refillable packaging and associated transformation processes. We work with brands, retailers and service providers across the supply chain. Why not check out our website or get in touch.